- Home

- Rotary Vacuum Paddle Dryer

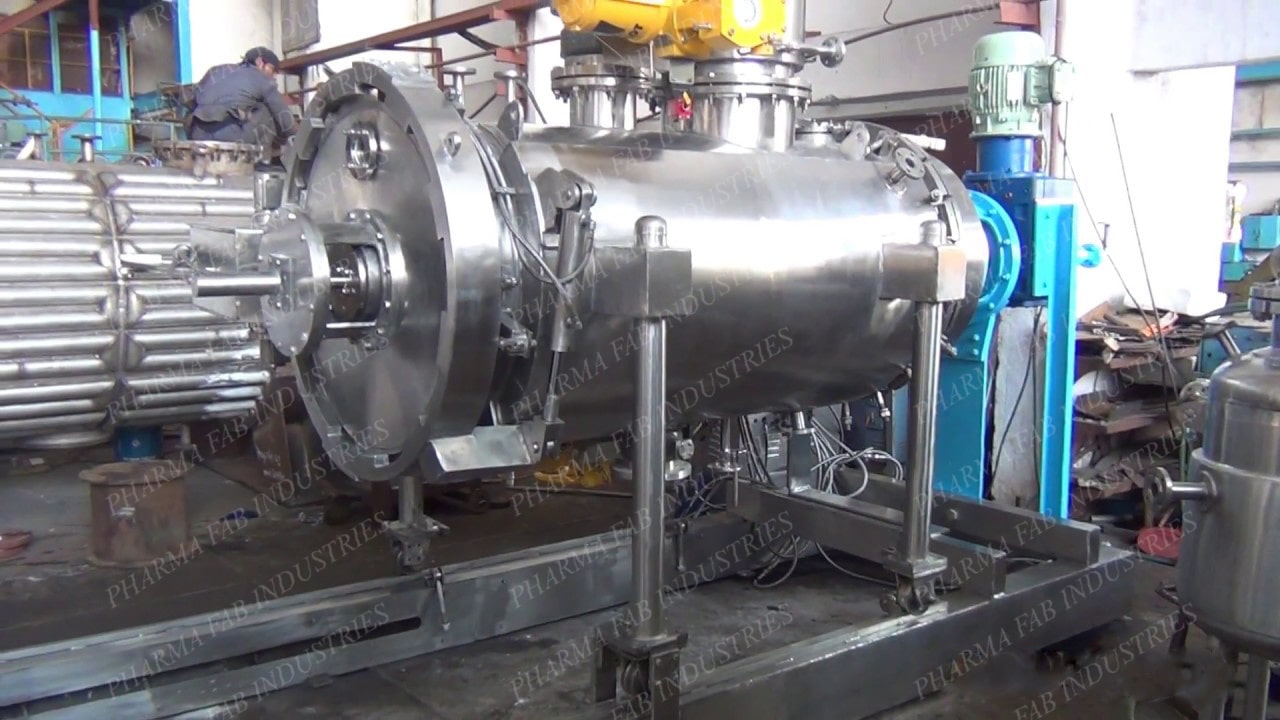

Rotary Vacuum Paddle Dryer

RVPD DRYER :

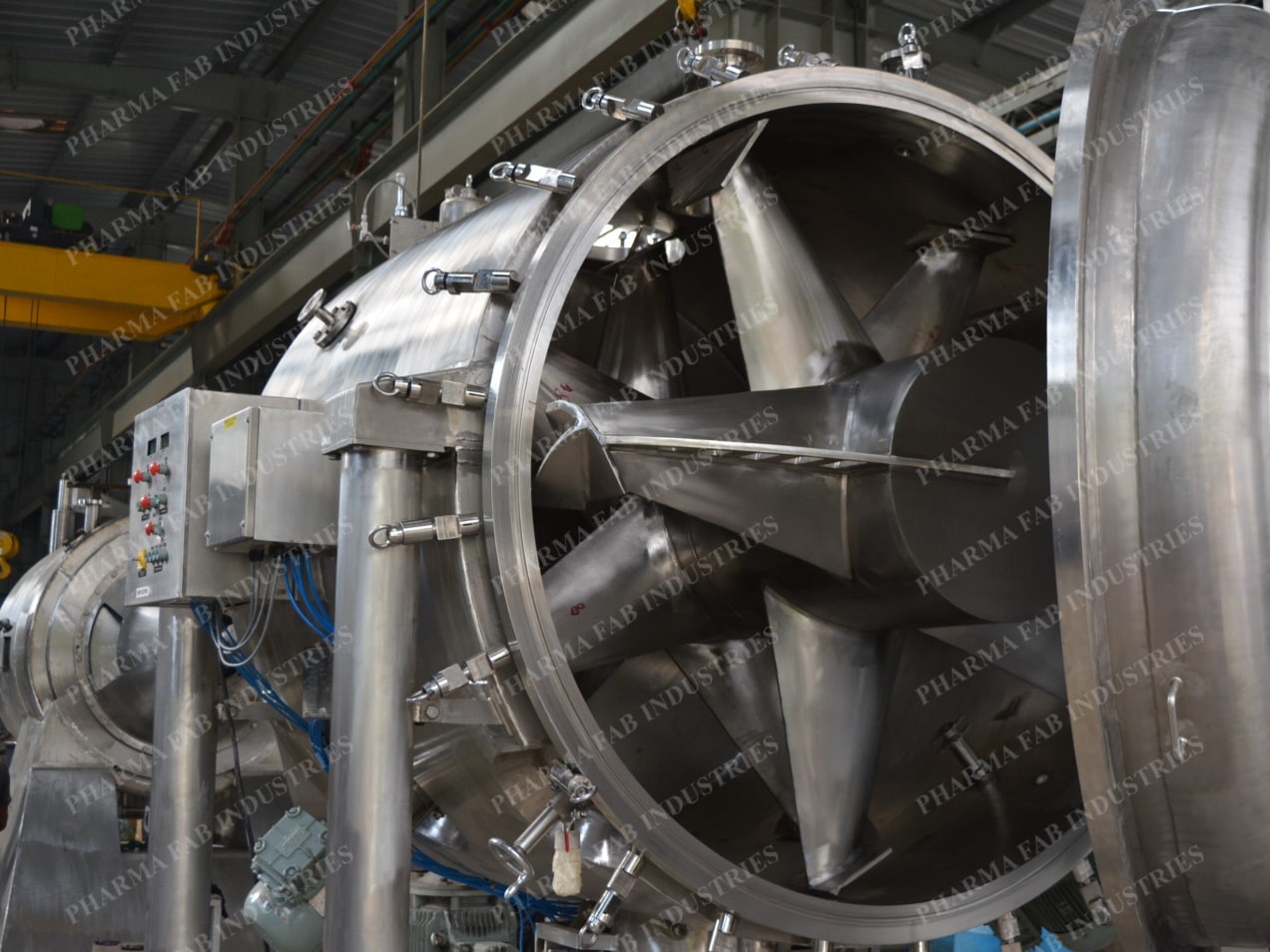

“ PHARMA FAB INDUSTRIES “ Rotary Vacuum Paddle Dryer / RVPD Dryer is a cylindrical vessel with a large Diameter Hollow shaft. The Jacket or Limpet Coil provided for heating the cylindrical shell. The shaft is attached with hollow paddles provided with specially designed scraper blades, which scrap the entire internal surface of the Dryer and continuously move and rotate the material thereby precluding the possibility of material remaining in contact with a hot surface for protracted periods of time.

The jacket/limpet coil and hollow shaft with paddles can be heated with hot water, steam, or any other thermal fluid capable of providing a large indirect heat transfer area. Cooling can be also be done by water, Brine, or any other refrigerant through the jacket and hollow shaft.

The hard facing of shaft provided in way of gland packing areas of trunions. Arrangements for Nitrogen purging provided. Bag cleaning arrangement with pulsation by Nitrogen jet injector provided.

Heavy-duty trunnions and bearing support the hollow shaft (agitator) and the drive are provided by means of a motor through reduction gears chain and sprocket.

In special cases, a stationary scraper blade can be provided to scrap the rotating agitator, for highly sticky materials

PRODUCT DESCRIPTION :

Rotary Vacuum Paddle Dryer Working Principle :

- Slurry / Wet cake is charged through the charging door while keeping a rotation of the agitator on. The vacuum is then applied to the Dryer along with Dust Catcher (mounted on the Dryer) Condenser and Receiver. The heating medium is passed through the jacket and Agitator. Vigorous evaporation of moisture takes place under a vacuum.

- The vapor passes through the Bag Filters of the Dust Catcher, goes into the Condenser and the Condensate is collected in the receiver. Evaporation under high vacuum and low-temperature results in faster recovery of maximum solvents. Adequate provision has been provided to cater for fluctuations in steam pressure/temperature, in Condenser cooling water temperature, moisture content of the feed, etc.

- The dry product is discharged via the discharge valve by reversing the Agitator rotational direction to the “Discharge” direction.

Vacuum Paddle Dryer Advantages

- Ideal for Temperature-sensitive materials.

- Improve product quality due to low-temperature drying system

- Almost 100 percent recovery of solvents.

- Low energy consumption

Rotary Vacuum Dryer Operation Conditions

- Vacuum: Up to even 0.6 torr

- Heating Temperature: 20° to 300°C

TECHNICAL SPECIFICATION :

These dryers give drying, mixing and breaking effects simultaneously. Wet cake or slurry is fed through charging door, while the agitator is rotating in clockwise direction, Vacuum is applied in the dryer and heating media is circulated in the jacket. Evaporation of moisture takes place under vacuum and vapors passes through the dust catcher into the condenser, where it is condensed and collected in the receiver. Dried material is discharged through discharge valve. The lump breaker rods are provided to achieve good drying effect.

The unique quick opening discharge valve is operated by a hand wheel. This allows quick discharge of material and permits the dry product to be directly packed into convenient 25/50 kg bags or drums without loss of powder material.

| MODEL NO. | TOTAL VOLUME (Lits) | WORKING VOLUME (Lits.) | OVERALL DIMENSIONS (mm) | POWER (H.P.) | |||

| A | B | C | D | ||||

| BEW-RVPD-1 | 100 | 50 | 2250 | 650 | 1400 | 400 | 3 |

| BEW-RVPD-2 | 200 | 125 | 2350 | 750 | 1500 | 400 | 5 |

| BEW-RVPD-5 | 500 | 250 | 2800 | 900 | 1600 | 400 | 7.5 |

| BEW-RVPD-10 | 1000 | 500 | 3900 | 1050 | 1750 | 300 | 10 |

| BEW-RVPD-15 | 1500 | 750 | 4500 | 1150 | 1850 | 300 | 12.5 |

| BEW-RVPD-20 | 2000 | 1000 | 5500 | 1250 | 2000 | 300 | 15 |

| BEW-RVPD-30 | 3000 | 1500 | 6250 | 1350 | 2200 | 300 | 20 |

| BEW-RVPD-40 | 4000 | 2000 | 5800 | 1450 | 2300 | 200 | 25 |

| BEW-RVPD-50 | 5000 | 2500 | 7550 | 1500 | 2400 | 200 | 30 |

| BEW-RVPD-60 | 6000 | 3000 | 8250 | 1750 | 2500 | 200 | 30 |

| BEW-RVPD-80 | 8000 | 4000 | 8450 | 1800 | 2700 | 200 | 40 |

| BEW-RVPD-100 | 10000 | 5000 | 10000 | 1850 | 2800 | 200 | 50 |

| BEW-RVPD-120 | 12000 | 6000 | 10400 | 1950 | 3100 | 200 | 60 |

| BEW-RVPD-160 | 15000 | 7500 | 11100 | 2200 | 3500 | 200 | 75 |

| BEW-RVPD-200 | 20000 | 10000 | 11550 | 2700 | 4100 | 200 | 100 |

| BEW-RVPD-250 | 25000 | 13000 | 12000 | 3000 | 5300 | 200 | 150 |

| NOTE: Design & Dimensions of above are subject to change without notice. | |||||||

CANTILEVER DESIGN :

This Machine can be provided in a single support (Cantilever) Design for Pharma, Clean room, Isolator applications. We can provide this cantilever design up to capacity of 6000 lits total volume.

Be directly packed into convenient bags, drums or can be connected to powder transfer systems to discharge without loss of powder material. This machine can be completely integrated with isolation system so as to avoid and exposure of the user to the potent product thereby providing complete operator safety

SALIENT FEATURES :

- Higher thermal efficiency due to the stirring action of product. high vacuum application and greater heat transfer area

- Improved product quality due to low temperature drying.

- Full recovery of solvent is achieved.

- Breaker bars are provided to break the lumps and disintegrate the particles size.

- Stealite or S.S. Surface is provided at gland packing area of shaft for its long life.

- Nitrogen purging arrangement is provided if necessary in stuffing box and at discharge point.

- Dust catcher cleaning arrangement with pulsation by nitrogen jet or air jet injector is provided.

- The design of paddles is such that reversal of electric motor direction is not necessary for discharging product. Hence the life of motor, gear box and equipment is increased.

- Dish end design is also manufactured on request.

- Sealing either stuffing box or mechanical seal with thermo-siphon arrangement.

APPLICATION :

Drying of granules, Powder of chemicals, Pharmaceuticals, Bulk drugs, Pigments, Dyestuffs, Fish & Sea food under vacuum. Size available from 100 liters to 25,000 liter