- Home

- Mass Mixer

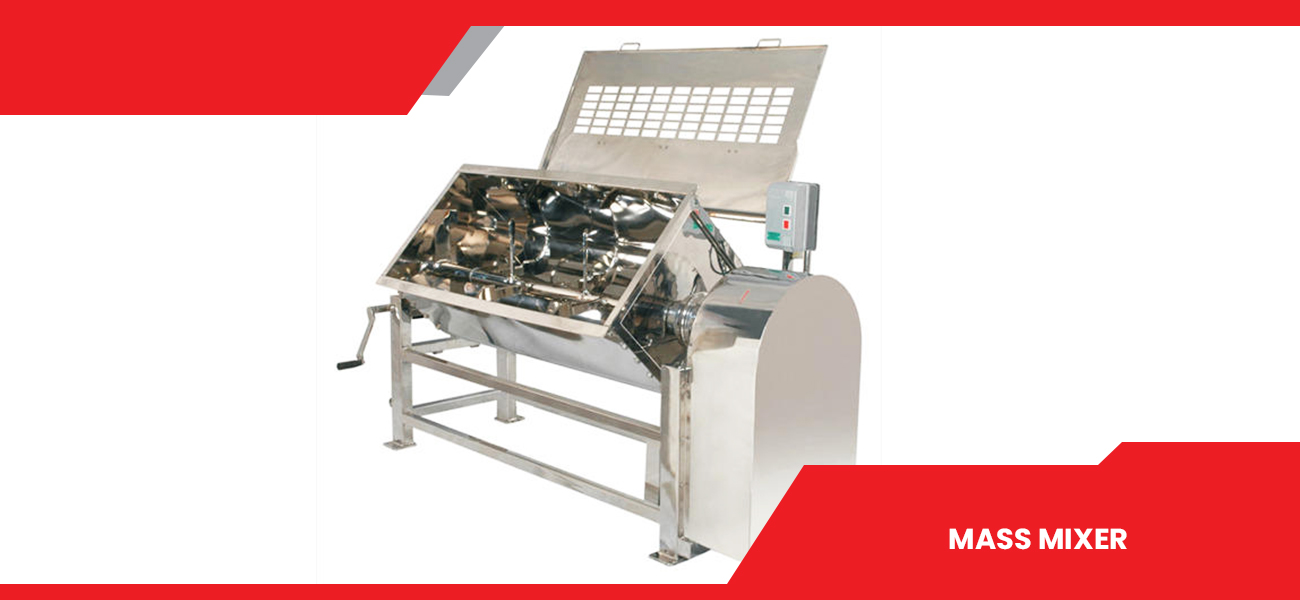

Mass Mixer

Application :

“ PHARMA FAB INDUSTRIES “ Mass Mixers are Ideal for mixing of Pharmaceutical powders, chemicals, food and confectioneries etc.

Process :

The Mass Mixer Machine is basically a mixing assembly wherein the mixing stirrer is in horizontal position in the container & have a single speed, simple rotation. The stirrer rotates around itself at a very slow speed inside the bowl and thereby achieving intimate mixing of dry or wet materials of Tablet Granulation, Powder, Chemicals, Food & Confectionaries Materials.

Because of a special design feature of machine & stirrer, the mass mixer can mix the sticky materials & also uniformly mixes the high dough type materials which are difficult to mix.

Salient Features of Mass Mixer :

- Capacity Range of Mass Mixers models to suit working volume 50,100,200,250,300Kgs.

- Design as per GMP and cGMP model

- MOC : SS 304 , SS 316 , SS 316 L

- Contact parts are of SS 316 / 316L and Non contact parts of SS 304 .

- Compact design , so it requires comparatively smaller floor space.

- Single stirrer with single speed for Dry & Wet mixing.

- As Seal of stirrer comes in contact with product, there may be any black particle contamination problem, after sealing bush got wear & tear.

- All moving parts are enclosed with safety guards. All safety guards are made out of SS 304 material in GMP model

- Thrust bearings are provided to carry out rigid thrust load.

- The container tilting system provided for easy unloading of material and easy cleaning.

- Simply designed SS 304 dust cover provided with one port for material for charging & inspection.

- Interlocking system with top dust cover, to avoid accident, during process. Specially design all moving parts provided with provision of easy lubrication.

Specifications :

- Shell : Consisting of ‘U’ trough of suitable dimensions. Construction of S.S. and side plates duly stiffened from outside and from inside with S.S.

- Mixing Mechanism : Paddle type beaters welded to the main shaft provide for efficient mixing of thick heavy material. PTFE gland mechanism provided at shaft ends which prevents ingress of external powder into the trough and prevents leakage.

- Charging : From the top , charging can be done through a lid provided by hinge and handle, hopper or Nozzle can be provided for additional spraying of additives.

- Discharge : By bottom discharge, slide Iris or Butterfly valve of suitable diameter, for regulated discharge.

- Drive : Consisting of suitable H.P. TEFC 3 phase ac 415v / 50 cycles motor coupled to suitable worm gear, with driving shafts mounted on suitable plummer block.

- Mounting : Mounted on suitable ISMC Section Stand, with protective covers for belts and couplings.

- Moc : All contact parts in S.S. 316 /SS 316 L and Noncontact parts in SS 304 Constructions. Complete unit with Acrylic transparent sheet with SS pipe Frame and all inside & Outside surfaces polished to mirror / matt finish

Optional Features of Mass Mixers:

- Variable speed drive or double speed of stirrer

- Flameproof Electrical .

Safety Features :

- All moving parts are enclosed with safety guards.

- Proximity limit switch