- Home

- Conta / Bin Blender

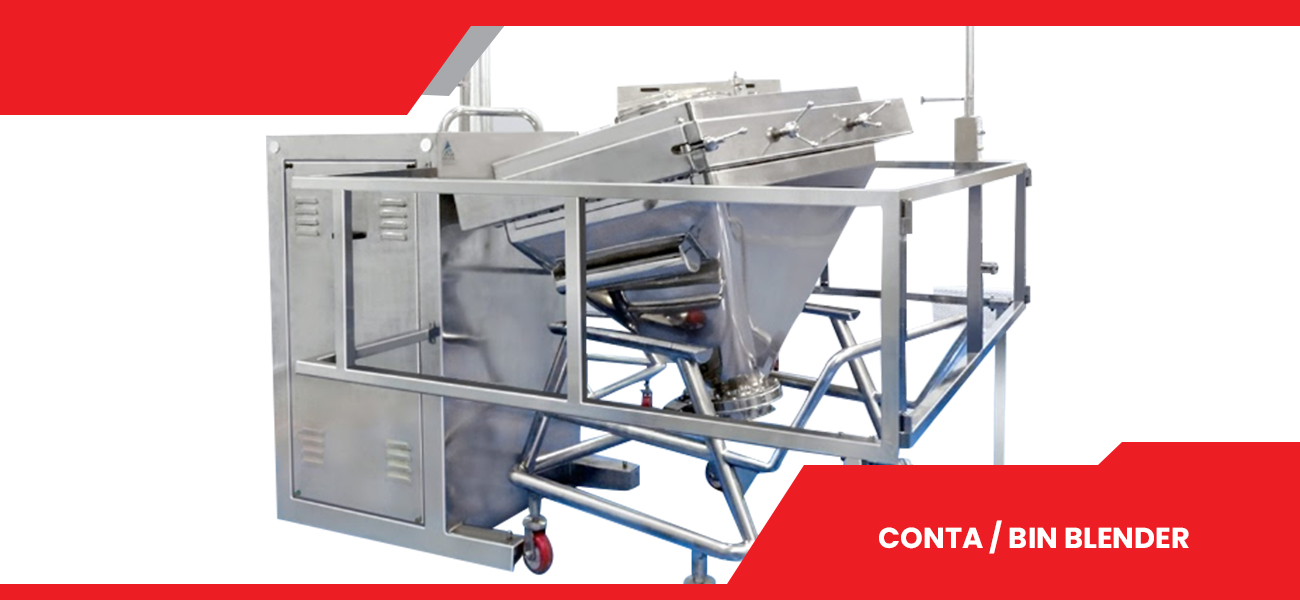

Conta / Bin Blender

Application :

“ PHARMA FAB INDUSTRIES “ Bin blenders or Container tumblers are used mainly for blending of dry powders for tablet production and capsule, which facilitates better flow for tablets and capsules. This is a closed contained, totally dust free single step transfer system. It can handle more than one size of container tumblers.

Process :

In granulation room the dry granules enter to the IBC container for blending through a dust free connection and the same IBC container is loaded over to the blender for blending. The IBC bin locked in the resting frame in 15° ,then lifted by hydraulic system in 15° inclined position , after that the IBC bin rotates for blending with 3 dimension action. This same container after blending loaded over the tablet press for unloading in to the tablet press hoppers.

SALIENT FEATURES of BIN Blender :

- Capacities Available from 25 kg to 500 kg batch size

- Design as per GMP and cGMP Model

- MOC : SS 304 , SS 316 , SS 316L

- All Product Contact parts SS 316 / SS 316L & Non Contact parts SS 304.

- IBC Bin Blender is ideal for dry mixing for lubrication of granules and homogenization mixing and conveying of the material to further process.

- Interchangeable of different capacity of IBC Bins can be used on same machine used for mixing.

- In the granulation room , the dry granules enter in to the container for blending through a dust free connection and the same container is loaded over to the blender for blending

- This is a closed and contained system. It is Totally dust free.

- Also another advantage is adaptability of this system to handle more than one size of containers, so processing of different sizes of production batches can be done in single equipment.

- Rigid drive with Reduction Gear box and Motor are Enclosed in the machine structure.

- Hydraulic power pack system is used for lifting of product bin for mixing.

- A suitable railing around the cage, with one entry point provided for the bin on the detachable trolley. Trolley with PU wheels for easy mobility.

- For free transfer of the particles ,the charging hole with cover is provided on top ,with quick opening and closing arrangement, with dust proof joints

- IBC Bin discharge is done with the help of butterfly valve

- Electric controls panel for smooth and ease in operation with cycle time.

Optional Features :

- AC Frequency variable drive (VFD) for product container.

- PLC Controls with HMI touch screen,

- Flame proof motor and Push Button station.

- Interchangeable Product Container

Safety Features :

- Limit switch on entry door to prevent the accidental operation of the cage,

- Overload relay protection & Emergency stop button.