- Home

- Ribbon Blender

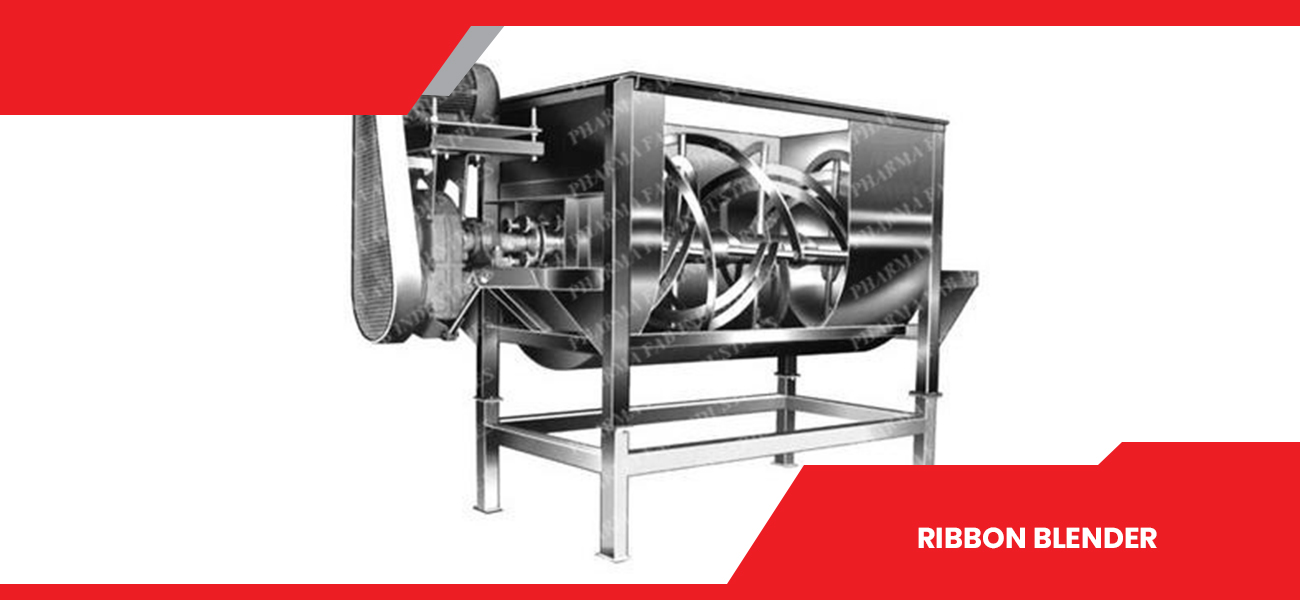

Ribbon Blender

Application:

“ PHARMA FAB INDUSTRIES “ Ribbon blender mixer is used for uniformly dry mixing and blending applications in the pharmaceutical, chemical, cosmetic, food, pesticides, detergents, and plastics industries. The Ribbon Blender comprises of a U-shaped horizontal trough, specially designed Double Helical Ribbon Agitator, rigid fabricated structure motor, gear box.

Process :

In operation, material is filled to the top of the outer ribbon. The shaft rotates at relatively low speed and the moving ribbons push the material back and forth mixing it. The outer ribbon rotation displaces the material from the ends to the center while the inner ribbon rotations move the material from the center to the ends. This counter-current action results in homogenous blending. Mixing is achieved in 15 to 20 minutes with 90 to 95 % or better homogeneity. The bottom discharge provided for unloading of the material and easy cleaning of the mixing drum. Specially designed self adjusting sealing arrangement of unique design is provided to ensure that no black particle enters into the mixing drum.

Salient Features :

- Available in Capacity 50 kg to 5000 kg. model.

- Design as per GMP and cGMP Model

- MOC : SS 304 , SS 316 , SS 316 L

- All Contact parts SS 316 / 316L & Non Contact parts SS 304.

- Uniform dry mixing process.

- The shape of container and mixing stirrer gives sufficient continuous movement to the powder / granules result in good quality. Minor ingredients are dispersed homogeneously without the need for pre-mixing.

- Double or triple action with blending occurring in the small voided areas immediately behind the blending ribbons.

- The interlocked acrylic covers of product container, enclosed drive& Overloads relay protection.

- Safety guards made from SS304 pipes provided in front of the m/c with limit switch.Panel fabricated from SS304 material with facility of three phase indication, D.O.L. Starter, digital timer & Amp. MeterMaximum care has been taken to ensure safe operation of the unit.Enclosed rigid drive with reduction gear box and motor. Worm reduction gear use for speed reduction.

- Food grade rubber gasket for butterfly valve at the discharge.

Optional Features :

- Additional chopper motor arrangement can be given for more uniform granules .

- AC Frequency Drive with Variable speed (VFD) ,

- Orientation of discharge is in side or centre.

- Jacketing for heating & Cooling,

- Vacuumized operation.

- PLC controls with HMI Touch Screen.

- Flame Proof Electrical.

Safety Features :

- Overload relay Protection and Emergency stop button

- Total drive transmission system enclosed

- Limit switch installed in the top lid ensure lid is closed